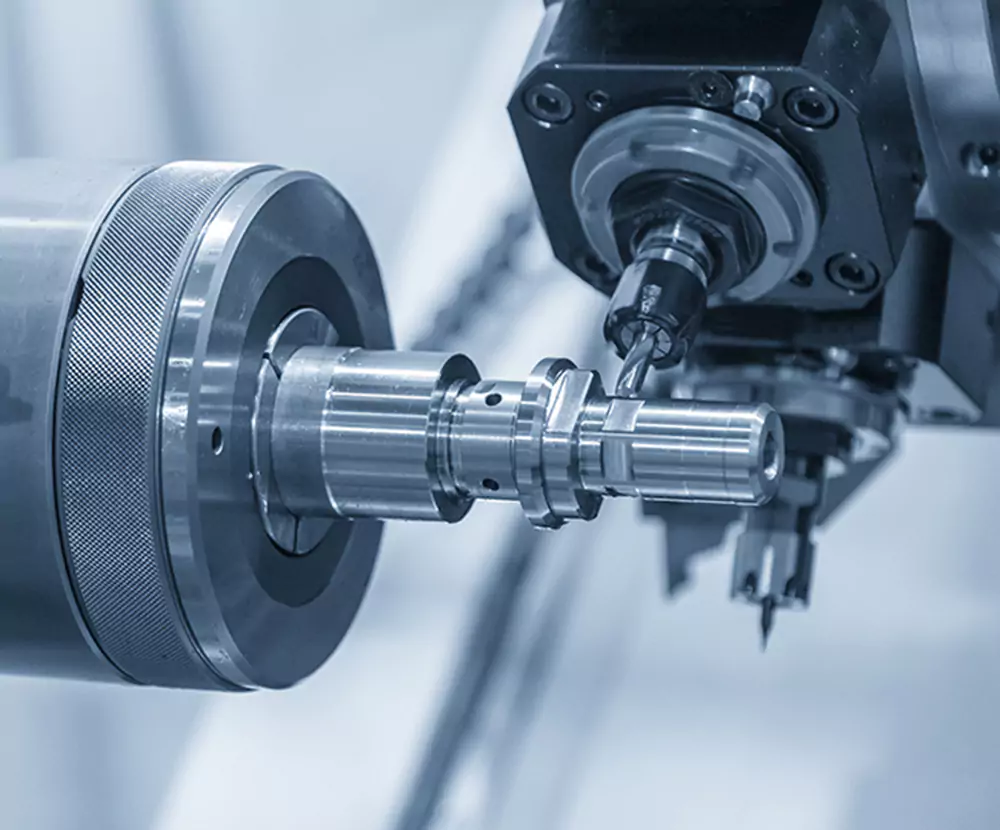

CNC Machining

We use advanced CNC machining equipment to guarantee accuracy and productivity when fabricating metal parts. With the greatest precise precision, we can create complex designs and close tolerances thanks to the sophisticated controls and tools on our CNC equipment. With our CNC machining capabilities, we can make metal parts that are of the highest quality and satisfy even the most exacting specifications, whether it is milling, turning, or grinding. Our knowledgeable professionals operate and program these devices to produce dependable and consistent outcomes, guaranteeing that every part satisfies the exacting requirements established by Metaltech fabricator trading and contracting.

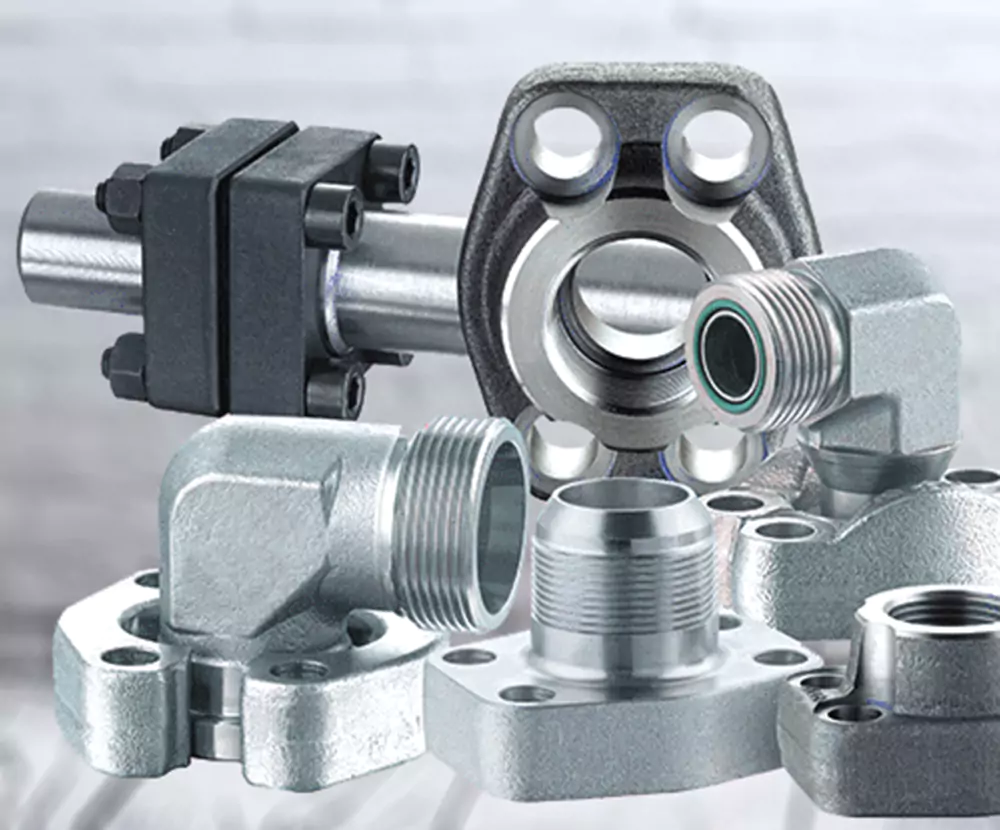

Hydraulic Fitting

Our hydraulic fittings guarantee leak-free connections and effective fluid transfer, which is essential for preserving the integrity of hydraulic systems. Usually constructed from brass or stainless steel, they can endure high-pressure hydraulic conditions. We offer the installation of hydraulic fittings, which entails careful assembly methods—such as tightening and sealing—to stop fluid leaks and guarantee the dependable functioning of hydraulic systems.

Hydraulic Hosing

The purpose of these flexible tubes is to carry hydraulic fluid, which powers machines and equipment while withstanding tremendous pressure. We increase the strength and longevity of our hydraulic hoses by building them with layers of reinforced materials, including textile braiding or steel wire. It's crucial to select the proper kind of hydraulic hose, taking into account things like compatibility with hydraulic fluids, temperature resistance, and pressure rating. It is essential to regularly examine and replace hydraulic hoses to stop leaks, preserve system integrity, and guarantee the secure and effective operation of hydraulic machinery.

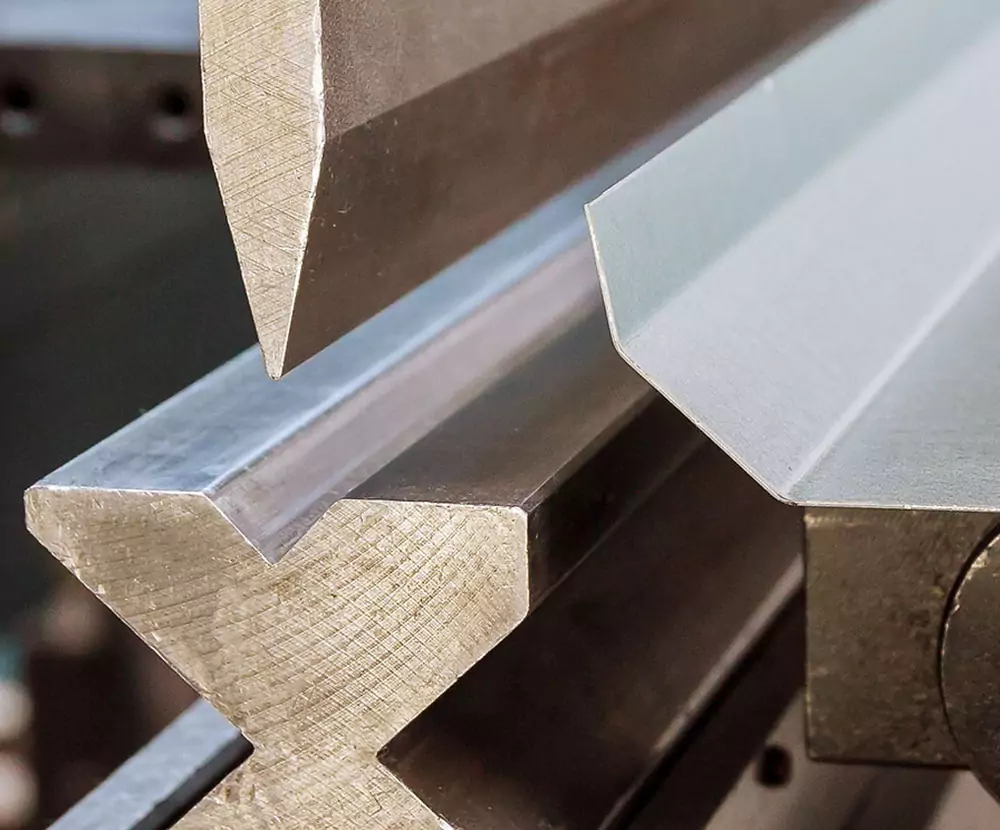

Lathe Works

Basically, lathes are used in many different sectors to make parts like pulleys, nuts, and shafts. Securing the workpiece in the lathe and choosing the proper cutting tool are the first steps in the procedure. To attain the required dimensions and surface finish, our lathe operators modify the machine's settings, such as the speed and feed rate. With accuracy and skill, we provide lathe works to meet a wide range of machining requirements. We guarantee the best quality in turning and shaping metal components thanks to our fleet of contemporary lathe equipment and knowledgeable staff of machinists.

Valve Maintenance

Maintaining valves is essential to making sure they work properly and last a long time in a variety of industrial applications. Valves are mechanical devices that open, close, or partially obstruct passageways to regulate the flow of gases, fluids, or slurries. Examining valves for wear, corrosion, and leaks is part of routine maintenance. In addition, it could entail lubricating, cleaning, and replacing deteriorated parts like gaskets and seals. We offer appropriate valve maintenance, which helps to keep machinery from breaking down, increases its lifespan, and guarantees the security and effectiveness of industrial operations. Furthermore, regular maintenance and timely repairs help minimize downtime and maximize a system's valve performance.

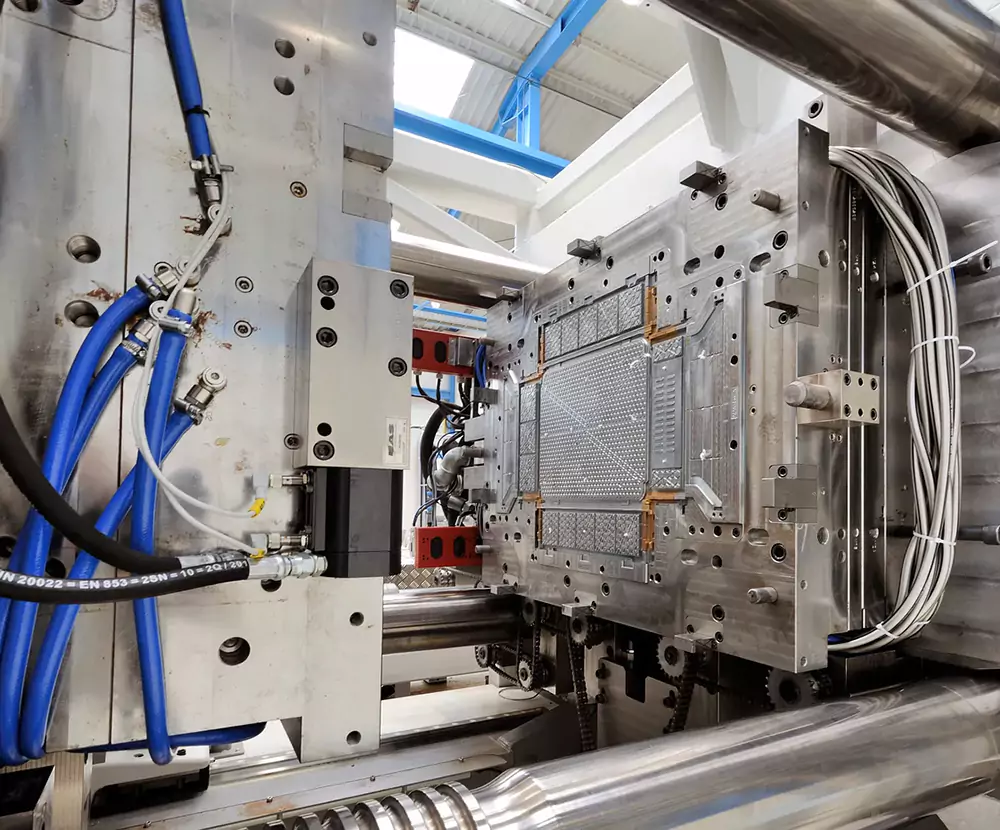

Injection Molding

The manufacturing method known as injection molding creates accurate and complex three-dimensional forms by pumping molten material—usually plastic—into a mold hole. The creation of numerous plastic parts and components, from tiny, delicate details to larger, more complex structures, is highly dependent on this technique. The first step in the procedure is to prepare the mold, which is usually divided into two parts and constructed of metal. The mold is then filled with the molten material and given shape by injecting it into it under high pressure. The finished product is released from the mold once it has cooled and solidified. For the economical and effective mass manufacture of repeatable, high-quality plastic parts, injection molding is a good choice.

Trading Division

Our trading division leads the way in international markets, skillfully navigating difficulties and providing value to clients across the globe. We acquire and sell a wide variety of metals, such as but not limited to steel, aluminium, copper, and other necessary raw materials, by utilising our extensive industry experience and network of reliable partners. The division's success stems from its dedication to comprehending market trends, reducing risks, and seizing new opportunities. For companies looking for supply chain innovation, efficiency, and dependability, our trading division offers more than just a transactional partner.